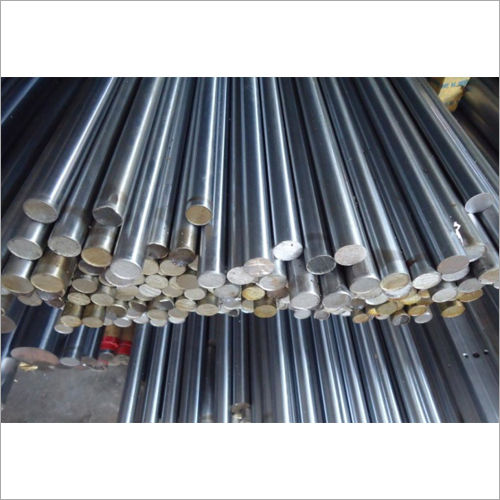

Hard Chrome Plated Rod

115.0 INR

Product Details:

- Load Capacity High, application dependent

- Thickness Chrome layer: 20-30 micron

- Tensile Strength Up to 700 MPa

- Application Hydraulic Cylinders, Pneumatic Cylinders

- Surface Finish Mirror Hard Chrome Plated

- Hardness HRC 58-62 (Hard Chrome Layer)

- Shape Round Rod

- Click to View more

X

Hard Chrome Plated Rod Price And Quantity

- 115.0 INR

- 1000 Kilogram

- 0.2m

- Rust Preventative Oil, Protective Wrapping

- Up to 6000 mm

- 0.2mm/m

- Strong Metallurgical Bond

- Carbon Steel (CK45, EN8, or as specified)

- Excellent, suitable for harsh environments

- Yes, per client specification

- Induction Hardened & Precision Ground

Hard Chrome Plated Rod Product Specifications

- Up to 700 MPa

- Hydraulic Cylinders, Pneumatic Cylinders

- Other

- Mirror Hard Chrome Plated

- Hard Chrome Plated Rod

- High, application dependent

- Customizable, typically 6mm to 100mm Diameter

- Chrome layer: 20-30 micron

- -20C to +200C

- Industrial Machinery

- Oil

- Round Rod

- HRC 58-62 (Hard Chrome Layer)

- Linear Motion, Piston Rods, Guide Rods

- 0.2m

- Rust Preventative Oil, Protective Wrapping

- Up to 6000 mm

- 0.2mm/m

- Strong Metallurgical Bond

- Carbon Steel (CK45, EN8, or as specified)

- Excellent, suitable for harsh environments

- Yes, per client specification

- Induction Hardened & Precision Ground

Hard Chrome Plated Rod Trade Information

- Cash Advance (CA)

- 100000 Kilogram Per Day

- 1 Hours

- No

- GOOD

Product Description

Hard Chrome

Plated Piston Rods

1- Available Rod Dia : 8mm to 125mm (Regular) and above dia as per customers requirement.

2- Length Available: 3 meter to 6 meter (Regular) and above as per customer demand.

3- Supplying conditions: Full length and cut to length as per customer requirement

Exceptional Chrome Layer Adherence

Our rods employ a robust metallurgical bond between the hard chrome plating and the steel core, ensuring the chrome layer remains firmly attached even under heavy loads and cyclic motion. This superior adherence minimizes the risk of flaking and wear, providing greater longevity in mechanical systems.

Optimal Precision and Straightness

Every rod is precision ground and induction hardened, guaranteeing straightness within 0.2mm/m. The surface finish achieves a remarkable roughness of 0.2m, resulting in minimal friction and improved performance in hydraulic and pneumatic cylinders. This manufacturing rigor delivers reliability in high-precision linear motion roles.

Designed for Demanding Environments

Engineered with a hard chrome layer thickness of 20-30 microns, these rods excel in resisting corrosion and wear, even in harsh environments. The high surface hardness and tensile strength (up to 700 MPa) ensure they can take on heavy loads with ease, maintaining functionality across extreme temperatures from -20C to +200C.

FAQ's of Hard Chrome Plated Rod:

Q: How are hard chrome plated rods manufactured to ensure durability and performance?

A: These rods are made using an induction hardening process followed by precision grinding. A hard chrome plating (20-30 microns thick) is then metallurgically bonded to the carbon steel core, resulting in a mirror-like, corrosion-resistant finish that meets stringent straightness and surface roughness specifications.Q: What are the primary applications for these hard chrome plated rods?

A: They are commonly used as piston rods in hydraulic and pneumatic cylinders, guide rods, and for linear motion in industrial machinery, thanks to their high straightness, mirror finish, and robust corrosion resistance.Q: When is it advisable to use hard chrome plated rods over standard steel rods?

A: These rods are the preferred choice in applications requiring high wear resistance, superior surface finish, and reliability in harsh environments, such as factories utilizing heavy machinery subject to frequent motion and load variations.Q: Where can I source customized hard chrome plated rods in India?

A: You can source these rods-customized to size, core material, and finish requirements-from leading manufacturers, distributors, suppliers, and traders across India who offer options tailored to your specifications.Q: What benefits do the rods' strong chrome layer adherence provide?

A: The secure metallurgical bond ensures the chrome plating remains intact during intense use, reducing the risk of peeling or flaking. This leads to longer service life, fewer replacements, and consistent performance even in demanding industrial settings.Q: How should these rods be handled and stored before installation?

A: Each rod is shipped coated with rust preventative oil and wrapped in protective materials. For best preservation, store them in a dry, sheltered space until ready for installation to prevent any surface contamination or corrosion.Q: Can I get hard chrome plated rods with specific dimensions or features?

A: Yes, customization is available for length (up to 6000 mm), diameter (typically 6mm-100mm), material (CK45, EN8, or as specified), and additional requirements to match unique application needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS