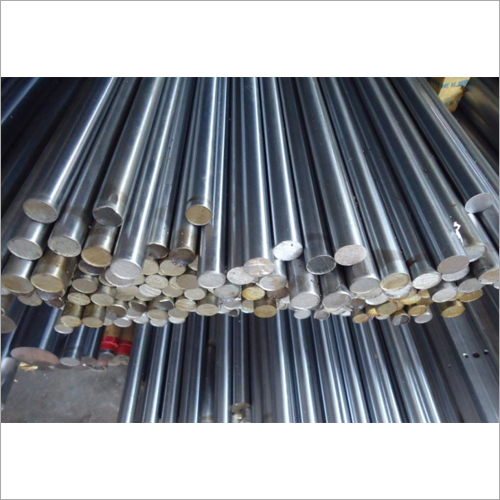

3 meter Hard Chrome Plated Piston Rods

160 INR

Product Details:

- Application Hydraulic Cylinders, Pneumatic Cylinders, Injection Molding Machines

- Shape Round

- Temperature Range -40C to +200C

- Hardness HRC 60-65

- Thickness Chrome Layer Thickness: 20-30 Microns

- Load Capacity Depends on Diameter; Customizable

- Tensile Strength Above 600 MPa

- Click to View more

X

3 meter Hard Chrome Plated Piston Rods Price And Quantity

- 115 , , Kilograms

- 160 INR

3 meter Hard Chrome Plated Piston Rods Product Specifications

- Hydraulic Cylinders, Pneumatic Cylinders, Injection Molding Machines

- Hard Chrome Plated Piston Rod

- Round

- -40C to +200C

- HRC 60-65

- Industrial Machinery, Hydraulic and Pneumatic Cylinders

- High Carbon Steel (CK45/EN8/EN19)

- Industrial, Mechanical, Automotive

- Chrome Layer Thickness: 20-30 Microns

- Depends on Diameter; Customizable

- Above 600 MPa

- 3 Meter Length

- Self-Lubricated / Requires External Lubrication Depending on Application

- Hard Chrome Plated (Mirror Finish)

3 meter Hard Chrome Plated Piston Rods Trade Information

- Per Month

- 1 Week

- All India

Product Description

Application :

- Available Rod Dia : 8mm to 125mm (Regular) and above dia as per customers requirement.

- Length Available: 3 meter to 6 meter (Regular) and above as per customer demand.

- Supplying conditions : Full length and cut to length as per customer requirement.

Technical Parameters-

- Material : EN 8D/CK-45

- Chrome Thickness: 20-25 Micron Minimum per side above as per requirement.

- Tolerance: ISO f7/f8

- Plating Hardness: 850HV-1100HV

- Surface Roughness: Ra 0.2micon or better

- Straightness: 0.1mm per meter

- UTS: 600-700 N/mm2 (min.)

- Y.S : 450 N/mm2 (min)

- Elongation: 16% Min.

- Quality: Half of the tolerance ISO f7/f8

- NSS Test: Minimum 120 Hours to 150 Hours

- Packing Condition: Paper Sleeve or Better for Transportation Purpose as per requirement.

Engineered for Performance and Durability

These hard chrome plated piston rods are built for strength and resilience, catering to demanding environments in industrial machinery, hydraulic, and pneumatic systems. Their high tensile strength and fatigue resistance ensure longevity and reliability during continuous operation, making them a preferred choice for manufacturers and end-users alike.

Superior Corrosion Resistance and Surface Finish

Thanks to a 20-30 micron hard chrome coating and compliance with the ASTM B117 Salt Spray Test, these rods withstand corrosive environments, maintaining their mirror-like finish. The Ra 0.2 m maximum surface roughness minimizes friction, helping optimize performance in various machinery.

Versatile and Customizable Solutions

Available in custom diameters and chamfered or tailor-made edges, these rods are suitable for diverse industrial, mechanical, and automotive purposes. Their high machinability and weldability cater to OEMs, distributors, and maintenance teams seeking adaptable, high-quality components.

FAQs of 3 meter Hard Chrome Plated Piston Rods:

Q: How are the 3 meter hard chrome plated piston rods manufactured to meet industry standards?

A: The rods are produced from high carbon steel (CK45, EN8, EN19) following ASTM A513, EN10305, and DIN2391 standards. The manufacturing process includes precision machining, induction hardening, and the application of a 20-30 micron hard chrome layer, ensuring exceptional straightness, hardness, and surface finish.Q: What are the benefits of the hard chrome plating on these piston rods?

A: The hard chrome plating imparts excellent corrosion resistance validated by the ASTM B117 Salt Spray Test, delivers a mirror-like finish (Ra 0.2 m max) for reduced friction, and enhances wear resistance, extending rod lifespan even in harsh operational environments.Q: Where can these piston rods be used in industrial applications?

A: These rods are ideal for use in hydraulic and pneumatic cylinders, injection molding machines, and various forms of industrial machinery. Their robust properties also make them suitable for mechanical and automotive sectors across manufacturing, maintenance, and assembly lines.Q: What is the process for customizing the size and edge condition of the rods?

A: Customization is available for diameter (12 mm to 150 mm) and edge condition (chamfered or as required). Customers can specify their requirements when placing orders, ensuring that the product precisely fits their application needs.Q: When is external lubrication required for these piston rods?

A: Depending on the application, the rods may either be self-lubricated or require external lubrication. High-load or high-friction environments typically benefit from additional lubrication to ensure optimum performance and longevity.Q: How does the rods core and surface hardness improve its performance?

A: A core hardness of HB 200-280 and surface hardness of HRC 60-65 provide high tensile strength (above 600 MPa) and robust fatigue resistance, ensuring the piston rod performs reliably under demanding pressure and load cycles.Q: What is the straightness tolerance and why is it important?

A: The rods maintain a straightness tolerance of 0.1 mm per meter. This high level of precision is crucial for smooth movement in cylinders, reducing wear and increasing efficiency in hydraulic and pneumatic systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS