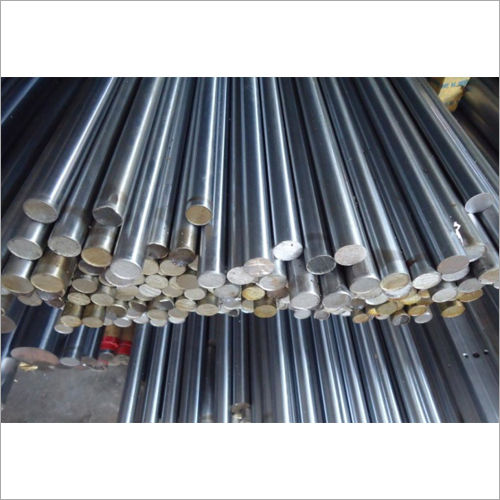

Hard Chrome Piston Rods

160 INR

Product Details:

- Load Capacity High Load Bearing (As per size/design specification)

- Engine Type Applicable for both Petrol and Diesel Engines (Hydraulic Systems)

- Application Hydraulic Cylinder, Pneumatic Cylinder, Shock Absorber, Industrial Equipment

- Lubrication Type Oil Lubrication

- Thickness 2530 micron (Chromium Layer)

- Surface Finish Hard Chrome Plated (Ra 0.2m, Thickness: 2530 micron)

- Tensile Strength 650850 MPa

- Click to View more

X

Hard Chrome Piston Rods Price And Quantity

- 160 INR

- 130 Kilograms

- High, Suitable for Dynamic Applications

- Excellent due to Hard Chrome Plating

- Diameter tolerance f7, h8, h9 as per DIN standard

- 0.2m

- Optional as per Customer Drawing/Specification

- Superior, Ideal for Highly Repetitive Machinery

- 0.1mm/1000mm

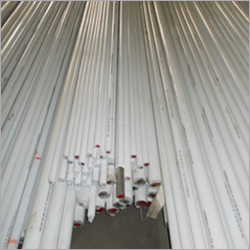

- Rust Preventive Oiled & Polywrapped

- Weldable Ends Option Available

- ISO 9001:2015 Certified Production

- Available as per Drawing or Sample

- 480 MPa

Hard Chrome Piston Rods Product Specifications

- 2530 micron (Chromium Layer)

- 650850 MPa

- Hard Chrome Plated (Ra 0.2m, Thickness: 2530 micron)

- Round (Rod)

- Customised (Diameter: 10mm - 100mm, Length: up to 6000mm)

- High Carbon Steel or Alloy Steel (e.g., CK45, 42CrMo4, EN8, EN9, etc.)

- -20C to +120C

- Surface Hardness 8501150 HV (HRC 6570)

- High Load Bearing (As per size/design specification)

- Hard Chrome Piston Rods

- Reciprocating, Hydraulic, Pneumatic

- Applicable for both Petrol and Diesel Engines (Hydraulic Systems)

- Industrial and Automotive

- Universal/Industrial Machinery

- Hydraulic Cylinder, Pneumatic Cylinder, Shock Absorber, Industrial Equipment

- Oil Lubrication

- High, Suitable for Dynamic Applications

- Excellent due to Hard Chrome Plating

- Diameter tolerance f7, h8, h9 as per DIN standard

- 0.2m

- Optional as per Customer Drawing/Specification

- Superior, Ideal for Highly Repetitive Machinery

- 0.1mm/1000mm

- Rust Preventive Oiled & Polywrapped

- Weldable Ends Option Available

- ISO 9001:2015 Certified Production

- Available as per Drawing or Sample

- 480 MPa

Hard Chrome Piston Rods Trade Information

- As per Order Per Month

- 1 Days

Product Description

Product Range :-

- Available Rod Dia : 8mm to 125mm (Regular) and above dia as per customers requirement.

- Length Available: 3 meter to 6 meter (Regular) and above as per customer demand.

- Supplying conditions: Full length and cut to length as per customer requirement.

Technical Parameters :

- Material : EN 8D/CK-45

- Chrome Thickness: 20-25 Micron Minimum per side above as per requirement.

- Tolerance: ISO f7/f8

- Plating Hardness: 850HV-1100HV

- Surface Roughness: Ra 0.2 micon or better

- Straightness: 0.1mm per meter

- UTS: 600-700 N/mm2 (min.)

- Y.S : 450 N/mm2 (min)

- Elongation: 16% Min.

- Quality: Half of the tolerance ISO f7/f8

- NSS Test: Minimum 120 Hours to 150 Hours

- Packing Condition: Paper Sleeve or Better for Transportation Purpose as per requirement.

Exceptional Corrosion & Wear Resistance

Thanks to thick hard chrome plating (2530 microns), these piston rods deliver excellent corrosion and wear resistance, making them ideal for high-frequency, dynamic operations. Their surface hardness ranges from 850 to 1150 HV, ensuring extended lifespan and reliability even under strenuous conditions.

Precision Engineering & Custom Options

Each rod meets strict straightness (0.1mm/1000mm) and surface roughness (Ra 0.2m) specifications. With diameter tolerances f7, h8, h9 in accordance with DIN standards, and ISO 9001:2015 certified production, customers benefit from precise, tailored solutions, whether for hydraulic cylinders, shock absorbers, or industrial equipment.

FAQs of Hard Chrome Piston Rods:

Q: How do hard chrome piston rods achieve their superior corrosion resistance?

A: The rods are plated with a thick hard chrome layer (2530 microns), creating a resilient barrier that protects against corrosion and oxidationeven in harsh industrial settingssignificantly extending service life.Q: What process is followed to ensure the straightness and diameter tolerance of the rods?

A: Manufacturing incorporates advanced machining and quality controls, guaranteeing straightness 0.1mm/1000mm and diameter tolerances f7, h8, h9 as per DIN standards. Each rod is produced in an ISO 9001:2015 certified facility for consistent precision.Q: Where can hard chrome piston rods be used effectively?

A: These rods are suitable for a wide range of machinery such as hydraulic and pneumatic cylinders, shock absorbers, compressors, and industrial equipment; theyre also compatible with both petrol and diesel engine hydraulic systems.Q: What customization options are available for these piston rods?

A: Customers may specify dimensions (diameter: 10100mm, length: up to 6000mm), select end fittings, choose weldable ends, or provide custom drawings/samples for tailored solutions to fit unique equipment requirements.Q: When should hard chrome piston rods be considered for dynamic applications?

A: They should be chosen whenever high fatigue strength, superior wear resistance, and reliable performance under repetitive, high-load conditions are neededsuch as in reciprocating compressors and highly repetitive machinery.Q: How are the rods packed and protected for delivery?

A: Each rod is oiled with a rust-preventive solution and securely polywrapped, ensuring preservation of surface quality and protection against environmental contamination during transit and storage.Q: What are the key benefits of using these piston rods in industrial setups?

A: Their high load-bearing capacity, longevity, minimal maintenance demands, and compatibility with various applications translate into reduced downtime and greater operational efficiency for distributors, manufacturers, and end users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS