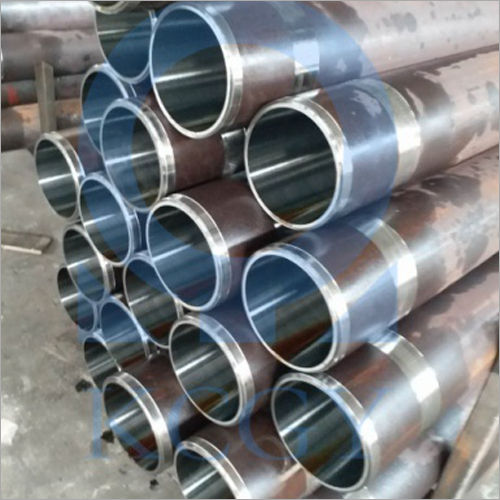

25 mm Hydraulic Cylinders Honed Burnished Tubes

150.0 INR/Kilograms

Product Details:

- Product Type Honed Burnished Tube

- Material Carbon Steel

- Shape Round

- Technique Cold Drawn / Seamless

- Surface Treatment Honed and Burnished

- Standard DIN 2391 / EN 10305

- Outer Diameter 28 mm Millimeter (mm)

- Click to View more

X

25 mm Hydraulic Cylinders Honed Burnished Tubes Price And Quantity

- 150.0 INR/Kilograms

- 1000 Kilograms

25 mm Hydraulic Cylinders Honed Burnished Tubes Product Specifications

- ST52 / E355 / CK45

- 25 mm ID

- 25 mm Millimeter (mm)

- Round

- Honed Burnished Tube

- Carbon Steel

- DIN 2391 / EN 10305

- Honed and Burnished

- 28 mm Millimeter (mm)

- Up to 6 meters or customized Meter (m)

- Cold Drawn / Seamless

- Metallic Grey

- 1.5 mm to 4 mm Millimeter (mm)

- 550 MPa Megapascals (MPa )

25 mm Hydraulic Cylinders Honed Burnished Tubes Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 1 Days

- All India

Product Description

Application :

- Available Internal Dia (Bore ID): 25mm to 300 mm (Regular) and above size as per customer requirements.

- Outer Dia available: as per customers required load and pressure.

- Length Available: 3 meter to 6 meter (Regular) and above as per customer demand

- Supplying conditions: Full length and cut to length as per customer requirement.

Technical Parameters :

- Material : ST52 in BK+S Condition and as per Customer demand.

- Tolerance: As per ISO H8/H9

- Surface Roughness: Ra0.3micron Maximum

- T.S. :>580 N/mm2

- Y.S.: > 520N/mm2

- Elongation: >16%

- Straightness: 0.1mm per meter

- Packing Condition: Bore covered by cap and plastic and Transportation purpose M.S.plate welded in bore both sides

Precision Manufacturing and Quality Standards

Engineered with cold drawn and seamless techniques, our hydraulic tubes adhere strictly to DIN 2391 and EN 10305 standards. Each tube is meticulously honed and burnished for a mirror-like internal finish, ensuring H8/H9 precision and outstanding straightness. This meticulous attention to quality translates to extended component life and reliable operation in demanding environments.

Versatility and Customization

These tubes are available in 25 mm inner diameter with outer diameters of 28 mm and wall thickness options between 1.5 mm and 4 mm. Lengths can be customized up to 6 meters, catering to unique installation needs. The tube ends can be supplied as square cut or chamfered, and multiple packaging options are available to ensure safe delivery.

Performance and Corrosion Resistance

Constructed from high-grade carbon steel such as ST52, E355, or CK45, these tubes boast a yield strength of 370 MPa and tensile strength of 550 MPa. Their honed and burnished surfaces offer minimal friction and high corrosion resistance, making them ideal for demanding hydraulic and pneumatic system applications.

FAQs of 25 mm Hydraulic Cylinders Honed Burnished Tubes:

Q: How are the 25 mm hydraulic cylinder honed burnished tubes manufactured to achieve high precision?

A: These tubes are produced using cold drawn and seamless techniques, followed by honed and burnished surface finishing. This precise manufacturing process delivers H8 or H9 tolerance for inner dimensions, straightness of 0.3 mm/m, and an inner surface roughness (Ra) of 0.2 m, assuring reliable fit and smooth operation.Q: What applications are these honed tubes most suitable for?

A: They are primarily used as hydraulic cylinder barrels and in pneumatic cylinders, where their dimensional accuracy, smooth bore, and high mechanical strength are essential for efficient, leak-free, and long-lasting actuator performance.Q: When should I choose custom length or end finishing options?

A: Custom length and specific end finishingsuch as square cut or chamferedis recommended when your hydraulic or pneumatic setup has unique design requirements, space constraints, or assembly needs. Tailoring these specifications ensures optimal integration and function.Q: Where are these hydraulic tubes typically supplied and used in India?

A: They are distributed, imported, manufactured, and supplied by various traders, retailers, wholesalers, and manufacturers across India. These tubes are used in sectors like manufacturing, construction, and heavy engineering wherever hydraulic or pneumatic cylinders are required.Q: What is the process for ensuring corrosion resistance in these tubes?

A: The tubes utilize high-grade carbon steel and are honed and burnished for a smoother inner surface, minimizing moisture retention. This, along with surface treatments and quality packaging (wooden cases, protective sleeves), provides robust resistance to corrosive environments.Q: How does the honed and burnished finish benefit hydraulic cylinder performance?

A: A honed and burnished inner surface reduces surface irregularities to Ra 0.2 m, lowering friction and wear on seals. This leads to smoother motion, extended seal life, reduced maintenance, and enhanced efficiency in hydraulic or pneumatic systems.Q: What are the key advantages of choosing your hydraulic cylinder tubes?

A: Key advantages include certified precision, high mechanical strength (yield 370 MPa; tensile 550 MPa), custom sizes up to 6 meters, excellent corrosion resistance, and compliance with DIN and EN standardsall ensuring dependable, long-lasting performance in a variety of applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free