6 m Hydraulic Cylinders Honed Burnished Tubes

150 INR

Product Details:

- Product Type Hydraulic Cylinder Honed Burnished Tubes

- Material Seamless Steel (Carbon or Alloy Steel)

- Type Honed Tube

- Shape Round

- Technique Cold Drawn, Honed and Burnished

- Surface Treatment Honed, Burnished, Phosphated, Painted

- Standard DIN 2391, EN 10305, ASTM A519, GB/T 8713

- Click to View more

X

6 m Hydraulic Cylinders Honed Burnished Tubes Price And Quantity

- Any order accepted Kilograms

- 150 INR

- 200-250 HB

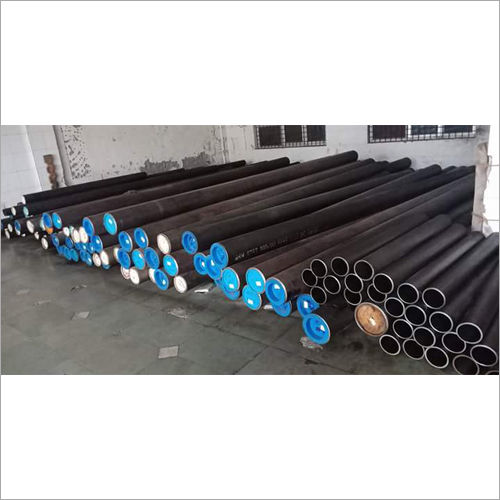

- Plastic Cap/End Protection, Packed in Bundles, Wrapped with Waterproof Material

- Hydraulic and Pneumatic Cylinder

- Varies as per dimensions

- 0.3 mm/m

- H8 - H9 as per standard

- 0.2 m

- Yes, with surface treatment

6 m Hydraulic Cylinders Honed Burnished Tubes Product Specifications

- Natural Steel/Black or Customized

- 2 mm to 50 mm

- Round

- DIN 2391, EN 10305, ASTM A519, GB/T 8713

- Cold Drawn, Honed and Burnished

- Seamless Steel (Carbon or Alloy Steel)

- 600 MPa

- 40 mm to 500 mm

- ST52, E355, STKM13C, SAE1020, SAE1045

- 50 mm to 510 mm

- Up to 6 meters

- Honed Tube

- Custom sizes available

- Hydraulic Cylinder Honed Burnished Tubes

- Honed, Burnished, Phosphated, Painted

- 200-250 HB

- Plastic Cap/End Protection, Packed in Bundles, Wrapped with Waterproof Material

- Hydraulic and Pneumatic Cylinder

- Varies as per dimensions

- 0.3 mm/m

- H8 - H9 as per standard

- 0.2 m

- Yes, with surface treatment

6 m Hydraulic Cylinders Honed Burnished Tubes Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- As per order Per Month

- Depends on order Days

- All India

Product Description

Application :

- Available Internal Dia (Bore ID): 25mm to 300 mm (Regular) and above size as per customer requirements.

- Outer Dia available: as per customers required load and pressure.

- Length Available: 3 meter to 6 meter (Regular) and above as per customer demand

- Supplying conditions: Full length and cut to length as per customer requirement.

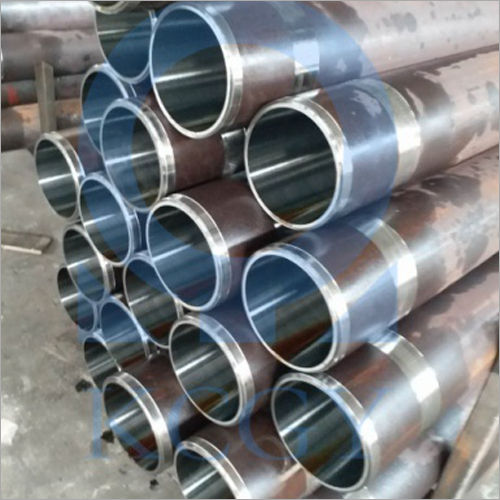

Technical Parameters :

- Material : ST52 in BK+S Condition and as per Customer demand.

- Tolerance: As per ISO H8/H9

- Surface Roughness: Ra0.3micron Maximum

- T.S. :>580 N/mm2

- Y.S.: > 520N/mm2

- Elongation: >16%

- Straightness: 0.1mm per meter

- Packing Condition: Bore covered by cap and plastic and Transportation purpose M.S.plate welded in bore both sides

Precision Engineering for Demanding Applications

Our honed and burnished tubes are engineered to deliver exceptional performance in hydraulic and pneumatic cylinders. With adherence to international standards and precise tolerance levels (H8-H9), these tubes provide smooth inner surfaces, reducing friction and ensuring reliable operation under high pressure. The robust material composition enhances longevity and operational efficiency in industrial settings.

Superior Corrosion Protection and Packaging

Each hydraulic tube undergoes thorough surface treatments, including phosphating and painting, to ensure unmatched corrosion resistance even in harsh environments. The tubes are carefully packaged with plastic end caps and waterproof wrapping to protect against damage during transportation and storage, maintaining integrity from our facility to your site.

FAQs of 6 m Hydraulic Cylinders Honed Burnished Tubes:

Q: How are the 6 m Hydraulic Cylinder Honed Burnished Tubes manufactured to ensure quality?

A: These tubes are produced using seamless cold-drawn techniques, followed by precision honing and burnishing processes to achieve optimal inner surface roughness (Ra 0.2 m) and straightness ( 0.3 mm/m). Strict adherence to standards such as DIN 2391 and ASTM A519 ensures consistent high quality.Q: What applications are best suited for these hydraulic honed burnished tubes?

A: These tubes are specifically designed for use in hydraulic and pneumatic cylinders due to their superior surface finish, hardness, and strength. They are widely utilized across industrial, construction, and engineering sectors demanding high-performance fluid power systems.Q: When should I choose these tubes with the specified hardness and tolerance levels?

A: Selecting tubes with a hardness of 200-250 HB and tolerances of H8-H9 is ideal for applications requiring longevity, minimum wear, and precise movement within hydraulic systems, especially when smooth operation and high-pressure resistance are essential.Q: Where can I source these hydraulic tubes in India?

A: These honed burnished tubes are available from a range of suppliers, distributors, manufacturers, importers, retailers, and wholesalers across India. Custom sizes and finishes can be ordered according to your specific project requirements.Q: What makes the surface treatment process important for these tubes?

A: The surface treatment, which includes honed, burnished, phosphated, and painted finishes, enhances corrosion resistance, ensures a smooth and consistent internal diameter, and extends the tubes service life, even under demanding operating conditions.Q: How does the packaging ensure product safety during delivery?

A: Each tube is fitted with plastic end caps for inner protection, bundled, and wrapped in waterproof material to safeguard against physical damage and environmental exposure throughout transportation and storage.Q: What key benefits do these tubes offer for hydraulic and pneumatic applications?

A: Key benefits include excellent dimensional accuracy, reduced friction for smoother piston movement, high tensile strength ( 600 MPa), robust corrosion resistance, customizable sizes, and compliance with international quality standards, ensuring enhanced system performance and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS